So much has been written about the Toyota Production System (TPS) that you may be wondering why in this day and age were the focus of most of this blog is on digitalization and Industry 4.0, I am bringing this topic back up? It should be no surprise that regardless of the paradigm shift that is going on Lean and the principles of TPS are still real and valid. The reason is that under all the tactical concepts that we in general refer to as "Lean Manufacturing" it addresses a basic characteristic of all manufacturing systems and that is that they are inherently chaotic! In fact they are a special type of chaotic system called Complex Adaptive System or CAS, a topic that I believe is critically important to understand in these transformational times.

|

| McElroy, Mark. (2000). Integrating Complexity Theory, Knowledge Management, and Organizational Learning. Journal of Knowledge Management. |

Before explaining what Chaos and CAS are and why I believe this to be true, I wanted to state the conclusion. The genius of TPS is that the concepts and strategies that it employees are directly built to use the characteristics of the CAS to its advantage, ie to increase value and productivity. The two fundamental concepts that are central to Lean and TPS that back this hypothesis are:

- Understanding that adaptability to change is critical. Lean provides for effective management small deviation and big changes with a focused and controlled manner with strong discipline, clear objectives and effective execution. Examples are Andons, Kaizen, Gemba, Hoshin Kanri, Poke Yoke, etc. that are designed to provide an effective way to deal with the repeatable patterns (good or bad) within the system.

- Understanding the boundaries between chaotic dynamics and order. Lean strives to coral the unpredictable nature of CAS by making a discrete non linear system more linear. Reducing batch size, making value flow, JIT, Heijunka, Kanban, SMED, etc. makes the system more continuous and less discrete and therefore more predictable.

In order to better understand this premise, I really need to provide a primer about Chaos and Complex Adaptive Systems. First a disclaimer - this is a diverse and complex topic and the following explanation is very high level and simplistic. Chaos sometimes is confused with randomness, however it is different. Here is a simple comparison:

This means that systems that exhibit chaotic behavior are impossible to predict but they have predictable patterns that repeat. On a side note; we as humans are very good at identifying patterns, which means we are inherently very good at operating in chaos. That is also what AI is good at and why its application in manufacturing context is so interesting and offers so much potential.

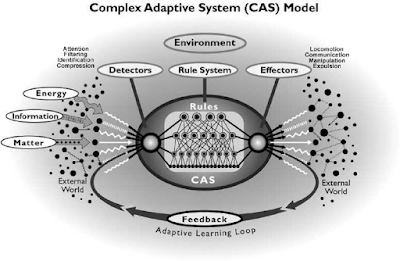

As mentioned a CAS is a special type of chaotic system that exhibit chaotic dynamics and emergent behavior and includes of course our favorite system the manufacturing organization. Other examples of CAS are weather, traffic, ant colonies, the stock market, social and organizations. A CAS behaves and evolves according to three key principles:

- Order and control is emergent. The overall behavior of the system of elements is not predicted by the behavior of the individual elements. There is a natural transition between equilibrium points through environmental adaptation and self-organization.

- The system's history is irreversible or irreducible. Irreversible process transformations cannot be reduced back to its original state. They evolve and their past is co-responsible for their present behavior.

- The system's future is often unpredictable. Non linear and therefore not predictable but yet have repeatable identifiable pattern. Predetermined patterns within their complexity describe potential evolutions of the system.

OK, now with this information we can reflect on what this means in the context of Lean and TPS. Jim Womack famously defined the 5 principle of Lean as a result of studying TPS and how it works. By looking at how each of these principles is directly designed to use the characteristic of a CAS the genius of TPS is revealed.

- Identify Value: This is in fact not directly related to the manufacturing being a CAS, it is really just a sound business principles. I.e. make sure to have clear objectives and know what to focus on- similar to Deming's "consistency of purpose". Identifying the value stream provides the framework for prioritization of how and where to optimize.

- Map the Value Stream: Understanding the value creation process and the details in the value stream helps in understanding the specific key attributes that impact the behavior of the system. In a CAS there are dependencies between key attributes and specific patterns that indicate either good or bad behaviors. This is to understand what in the value stream may trigger unwanted states, ie.e the famous "butterfly effect". For example the rectangles drawn on the weather forecast indicating that a Tornado is likely.

- Create Flow: Make sure that the production value stream flows since systems that flow are continuous and more linear in contrast to nature of discrete "stop and go" type of behavior. Reducing the unit size (one piece flow) eases flow, with the smaller the unit the better. Without consistent flow the system becomes more non-linear and may exhibit catastrophic patterns. For example getting stuck behind the guy who can't out of the way when boarding a plane (exemplified by Mythbusters).

- Establish Pull: Consistent flow can be nearly guaranteed if you pull rather than push the elements of the system. It secures blockages are identified immediately and removed, simply because you can't pull with something in the way. Think what happens when you are behind two trucks overtaking on a highway causing traffic to backup.

- Seek Perfection: This principle is to ensure that we can keep the CAS in states that we can predict. By striving to keep the manufacturing system as close as possible to linear (consistent flow) we can predict and guarantee performance and behavior. However it also provide tools to identify unwanted patterns and ways to quickly address states that are undesirable.

Toyota has always advocated a cautious approach to new technology and that is a a problem. The n-1 approach to technology advocated by Lean (the use of proven technology, not the latest and greatest) is sometimes used as an excuse to maintain status quo. In these times of change with all the new digital technology available this seemingly puts Lean companies at a disadvantage. However if you approach these technologies as a way to Lean, to reduce waste, to create flow and execute pull then the value of the technology can easily outweigh the risk. In addition the n-1 concept was really meant for production equipment, i.e. to not increase the risk of interrupting the production flow and quality issues.

Its important to understand how digital technology can be used to support a Lean system. Remember the new paradigm offers an order of magnitude productivity increase and herein lies key motivator. Digital transformation needs to support a lean system, it has provide additional tools in the Lean toolbox. Digital technology can be catalyst to a Lean organization where continuous improvement happens faster and more effectively and that is how the "order of magnitude increase" is realized.

So the genius of TPS is simply put that Toyoda understood behavioral dynamics of his manufacturing operation even without knowing its a CAS and was able to put together a management strategy to directly impact the characteristics of the system with optimization in mind. When operational principles are nicely aligned with the science behind it there its not a surprise that its successful. We should now do the same to transform lean operations with digital tools so that we can hit the digital transformation jackpot.

No comments:

Post a Comment